Multi spectral light source

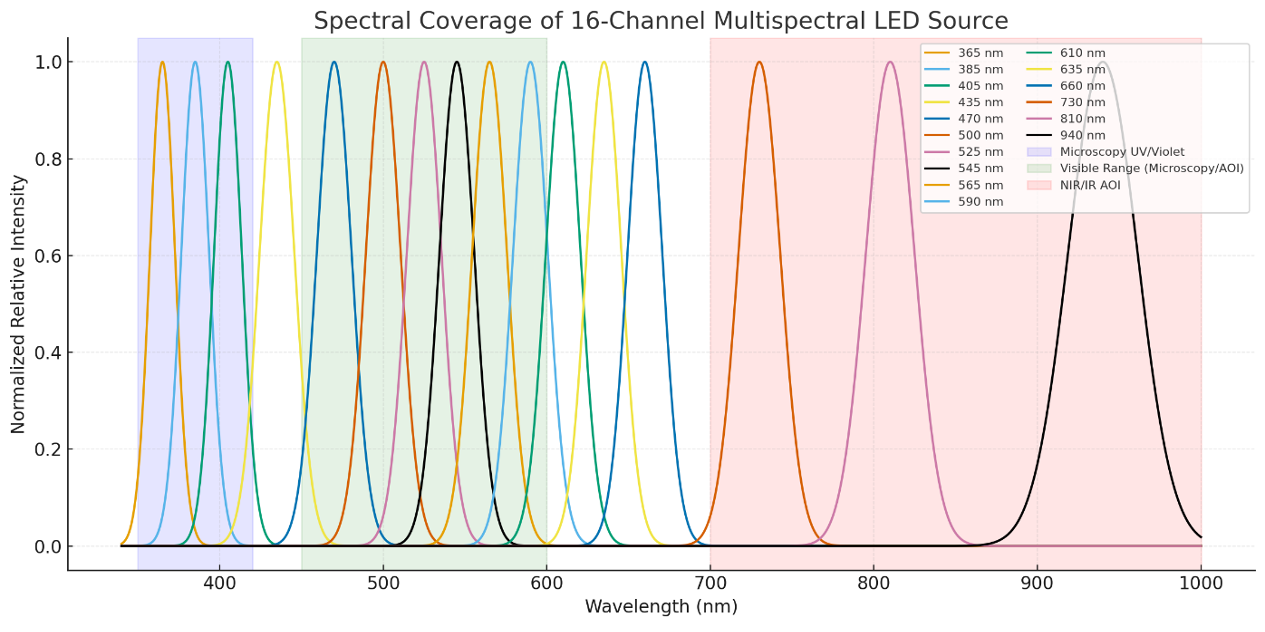

Our multi spectral light source provides full UV-VIS-NIR coverage and allows users to configure any subset of 16 bands:

The bands serve different purposes and allow to cover multiple in parallel, especially relevant for Automated Optical Inspection (AOI) used in semiconductor industry where high throughput is crucial when looking for contamination:

- Blue-shaded region (350–420 nm): UV/Violet bands, mainly for microscopy fluorescence and AOI residue detection to increase yield in semiconductor industry. Flux residues, organics and thin-film delamination can easily be identified.

- Green-shaded region (450–600 nm): Visible range for microscopy, and colorful high contrast imaging

- Red-shaded region (700–1000 nm): NIR/IR region, light penetrates layers and can uncover buried particles and allows to find micro cracks in substrates.

In many fields this light source can replace existing mercury lamps adding alle the benefits that come with LED technology (life time, speed, temperature, costs, …).

Other outstanding features:

- 10Hz full spectral rate: Perfect sync with high-speed area-scan cameras (Individual images acquired at 160Hz)

- Spectral Flexibility Without Hyperspectral Overhead: Rich data, small footprint and simple integration

- AI-Supportive: Clean, co-registered spectral planes feed defect-classification models without special preparation

- Cost & Lifetime Advantage: Fraction of the cost of LCTF/AOTF, long LED lifetime